Company Profile

Company Profile

Agel Langgeng was established in Bekasi in 1991. Our first product, Relaxa Candy, was launched in 1993. Not only did Relaxa become the first fragrant candy introduced to the market, but Agel also birthed an entirely new category and continues to be the market leader ever since. The increasing sales of Relaxa drove Agel to open a new factory in Pasuruan, East Java, to focus on the production and supply for the eastern Indonesia region.

Supported by high-tech machinery from Europe and Japan in producing high-quality products for our consumers, Agel’s success story in launching new categories did not end there. Following this accomplishment came Gingerbon in 1998, the modern ginger candy which created its category; Espresso, the first coffee candy with center fill in 2004; Bontea Green, the first green tea candy with lemon centerfill in 2008. In 2010, Agel started to produce Kapal Api Candy; a candy based upon our best-selling coffee.

In 2011, Agel penetrated the biscuit market with Oatbits; oat biscuits with fruit bits. Recently, Agel launched Delbi’s Kopyor, biscuits made of kopyor coconut.

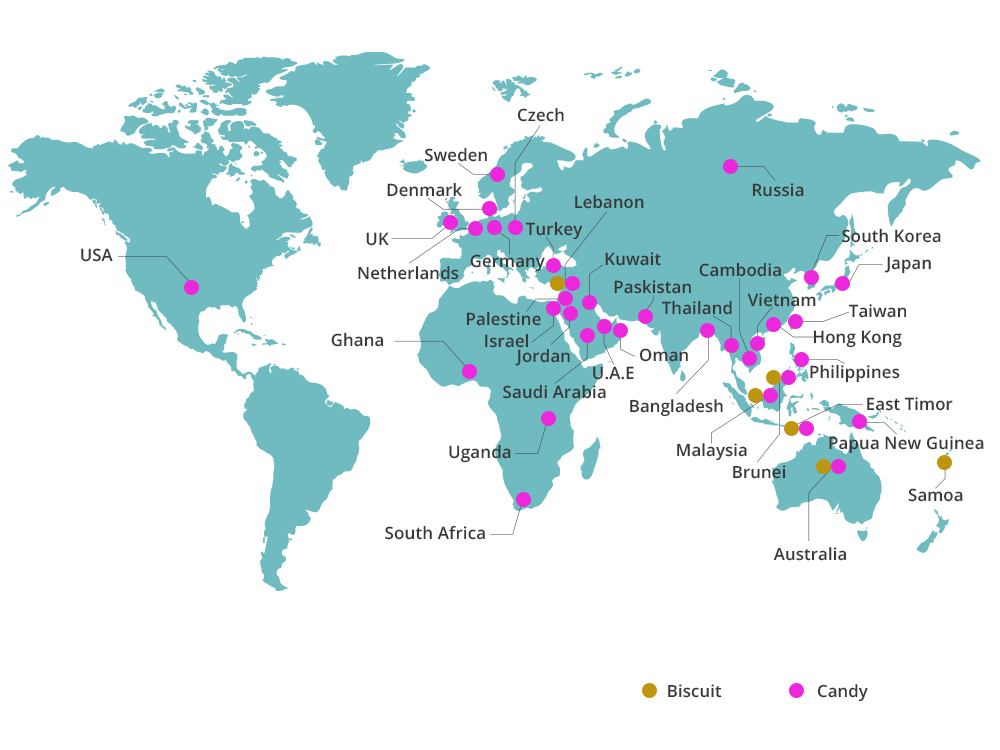

With its rapid growth, Agel has become one of the largest confectionery and biscuit producers in Indonesia.

Vision :

To lead the confectionery and biscuit market by spreading joy through tasteful products that colors people’s daily lives.

Mission :

To create a consumer centric company that is admired by:

1. ensuring a process of innovation, high quality products, future development of the business and

2. driving economic value through the right blend of skills, partnerships,systems, structure and people synergy.